Branding Techniques

Put your logo on it

Our techniques for a unique brand workwear and promotional clothes

Creating customised work uniforms means much more than just printing or embroidering garments with your company logo. The basis is continuous research and study of new materials, tried and tested to extend the range of proposals.

Cast Bolzonella's Style Department offers a wide range of advice on personalisation techniques, from screen-printing to embroidery, and even more special techniques, to make your workwear recognisable and unique.

Discover our proposals among those we offer below:

• Embroidery • Screen printing • Plotter • Labels and applications • Laser • Tricolour woven label

|

Embroidery adds value and elegance to workwear and, because of its resistance, preserves even the smallest details over time.

This technique still retains its handcrafted quality thanks to our 'punching' staff. Starting from the graphic file of your logo, the "embroidery program" is created, which communicates the sequence and density of the needle stitches of the embroidery machine, thus starting the customisation.

Depending on the workwear to be customised, we have yarns available in viscose, polyester, metallic, fireproof, glow-in-the-dark, reflective, up to a special opaque filament which, thanks to the percentage of ceramic, makes it unique.

Another very important aspect is that the yarns we use comply with Oekotex standards.

|

|

Plain embroidery

This is the most traditional technique: the embroidery machine "spins" the logo thanks to a dense frequency of stitches made with coloured threads.

The range of spools of thread selected by us increases its versatility, to adapt to personalisation on any type of fabric. For example, on flame retardant fabrics we have a flame retardant yarn that maintains the characteristics of the fabric.

We recommend this yarn for customising jackets, waistcoats, sweatshirts, trousers, piqué polos, jackets, fleece, caps and dungarees.

|

|

Embroidered Patch

It is an embroidery with a shaped fabric on the bottom. Once decorated, the patch can be applied to the garment using border stitching, or it can be heat-sealed using a special vinyl that melts with the heat of the press and acts as an adhesive.

In addition to yarns, we also have a range of fabrics to choose from: felt, nylon, Turkish satin, reflective, velvet effect, imitation leather, etc.

We recommend the choice for personalisation on jackets, waistcoats, sweatshirts, trousers, piqué polos, jackets, fleece, caps and dungarees.

|

|

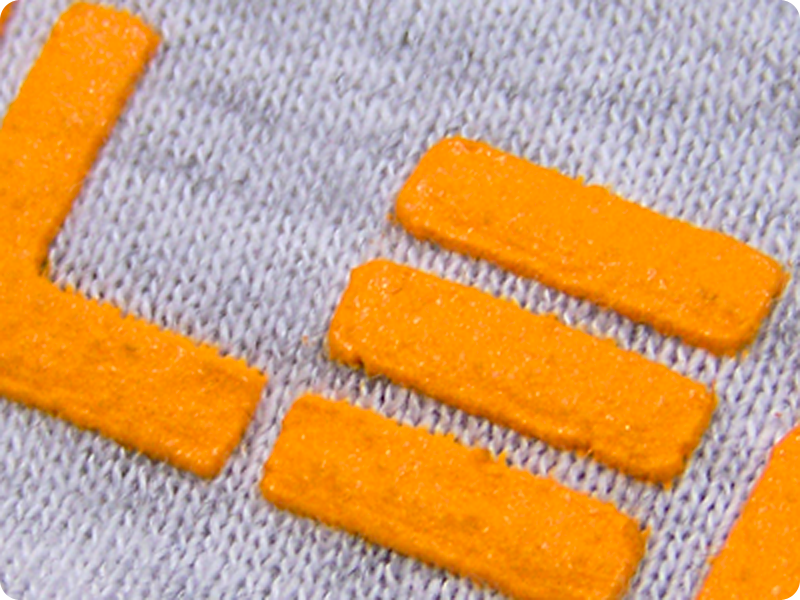

3D Puff embroidery

This technique allows to create reliefs up to 4mm (0,16")thick, thanks to special 3D materials inserted under each stitches.

This is a high stitch density embroidery, particularly suitable for large surfaces and logos with simple lines.

3D embroidery is used to customize all garments but is not recommended for very light ones, such as jersey T-shirts, etc.

|

|

Embroidery on reflective fabric

This is an embroidery made on a reflective fabric that guarantees visibility even in twilight or darkness. This type of personalisation can be done directly on the garment, or as a patch to be applied to workwear at a later date. We recommend embroidery on reflective fabric for workwear to be used outdoors and/or in conditions of low visibility, but also for areas where loads and machinery are handled.

|

|

Screen printing is one of the oldest printing techniques. It uses a frame, which was once a very light silk fabric, where the personalization is imprinted thanks to a light-sensitive gel. In this way a "mask" is obtained for applying the ink to the fabric. Using special inks, it is possible to obtain original effects, to give a unique look to your garments personalization.

|

|

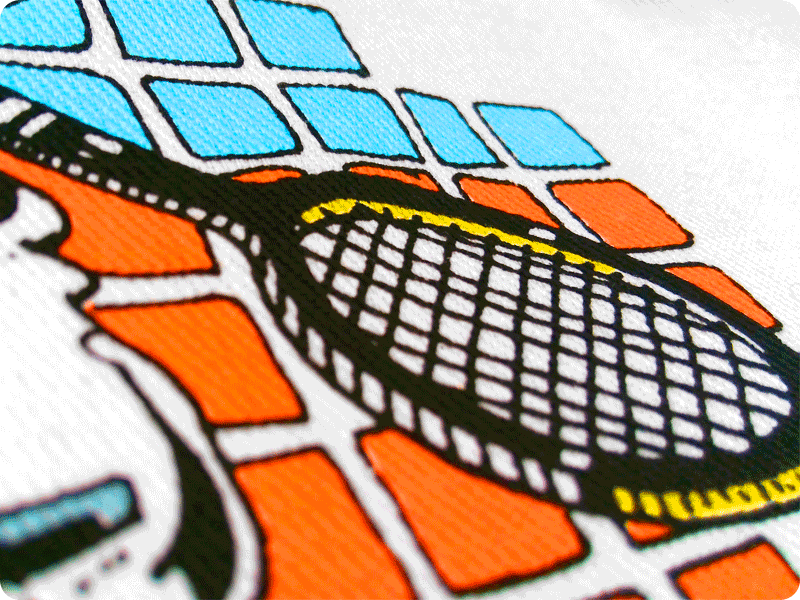

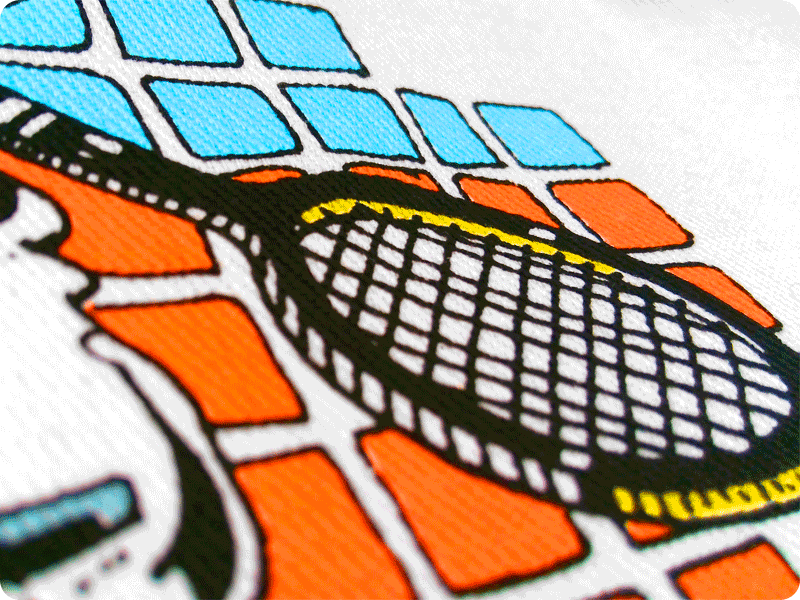

Multicolor screenprint

Using multiple silk-screen frames, it is possible to put on one or more inks, allowing to create color shades as well.

Particularly suitable for polo shirts and promotional T-shirts, it can be used on all our workwear lines.

To keep the print quality intact for a long time, we recommend washing the garment in reverse.

|

|

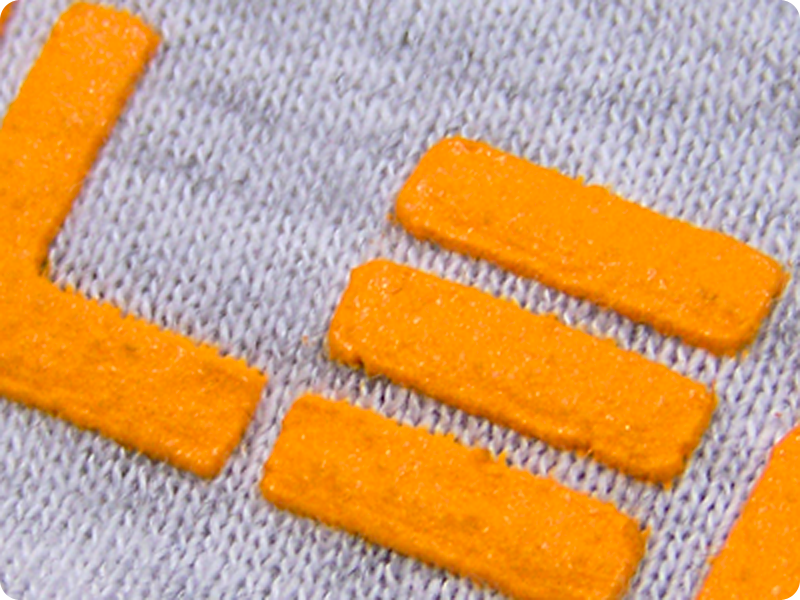

High density printing

Thick or relief printing allows for personalisation with a slight thickness.

It is a technique that requires great precision because it is obtained by using special thick screen printing frames and passing several layers of ink.

We recommend this type of processing for unpadded workwear.

We recommend it for customising sweatshirts, polo shirts and t-shirts.

|

|

Puff printing

Puff printing provides a softer relief effect than thick printing. It is achieved by adding a special swelling additive to normal screen printing ink.

Thanks to a precise control of the passage through the oven at high temperature, the print swells, giving a pleasant relief effect to the customisation.

We recommend it for customising sweatshirts, polo shirts and T-shirts.

|

|

Heat transfer printing

Another very popular technique for personalising workwear is transfer. This consists of negative printing of the personalisation on a special paper film called transfer.

If the logo has simple lines and few colours, it can be screen printed, while more complex logos with nuances and many shades are printed using special printers.

The logo is then positioned on the garment and indelibly fixed using a heat press.

This type of workmanship lends itself to personalisation of all the garments in our range, making it possible to apply the logo even in difficult or unusual positions.

In order to maintain the quality of the print for a long time, we recommend washing the garment inside out and not ironing over the application.

|

|

|

|

This is a personalisation technique using coloured heat-sealable vinyl. A special plotter cuts the films with a blade, reproducing the logo.

Once the surplus has been eliminated, a manual process known as peeling is used to position the film on the garment, where a heat-press indelibly fixes it to the fabric.

This type of processing lends itself to the personalisation of all the garments in our range, making it possible to apply it even in difficult or unusual positions.

The vinyls are single-colour, but alternatively overlaps can be made with other colours, even with special effects: glitter, embossed, textured, metallic, velvety, luminescent, reflective, etc.

To maintain the quality of the print intact for as long as possible, we recommend washing the garment inside out and not ironing over the application.

|

|

|

|

VIPLA and Digital patches

This is a polyurethane label that is printed using a plotter and heat applied to the garments to be personalised. With a solid or shaped bottom, it offers brilliant colours and the possibility of colour shading.

This customisation technique is well suited to t-shirts, polo shirts, sweatshirts, trousers, jackets and overalls, making it possible to apply it even in difficult or unusual positions.

|

|

Rubber patch

This is a rubber label, possibly printed, which can be embroidered or applied by embroidery, resulting in an impactful and very professional effect.

Given the nature of this personalisation, it is only recommended on heavy items such as work jackets and coats.

|

|

Woven patches & labels

This type of personalisation allows very high precision and strength. The labels are spun directly by a special machine, in the company colours, and are then attached to the workwear to be branded by stitching or heat-sealed by means of a heat-press.

The result is a lightweight, durable and highly detailed personalisation that will never fade.

We recommend the choice for personalisation on jackets, waistcoats, sweatshirts, trousers, polo shirts, t-shirts, vests, fleece, caps and dungarees.

|

|

Vintage embroidery patch

An original and impressive customisation is the vintage one. This consists of a patch where the edge of the fabric is frayed, giving a worn look.

We recommend this for customising sweatshirts and polo shirts.

|

|

|

|

Embroided laser cut letters

This is a portion of special fabric onto which the embroiderer sews a thick border cord. The excess is then torn off, keeping the inner part firmly anchored by the seam itself.

To make this application even more special, a rubber band can be sewn together to create a rounded effect.

This customisation is very well suited to work and promotional sweatshirts.

|

|

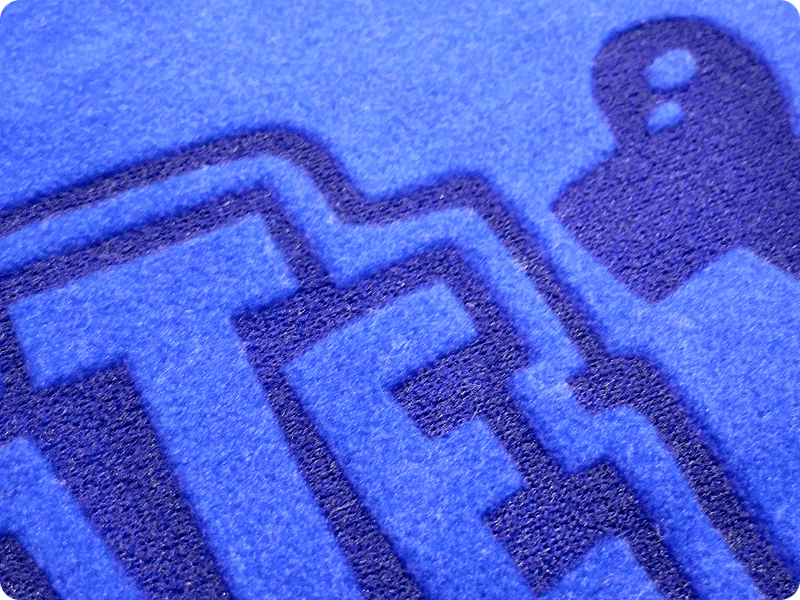

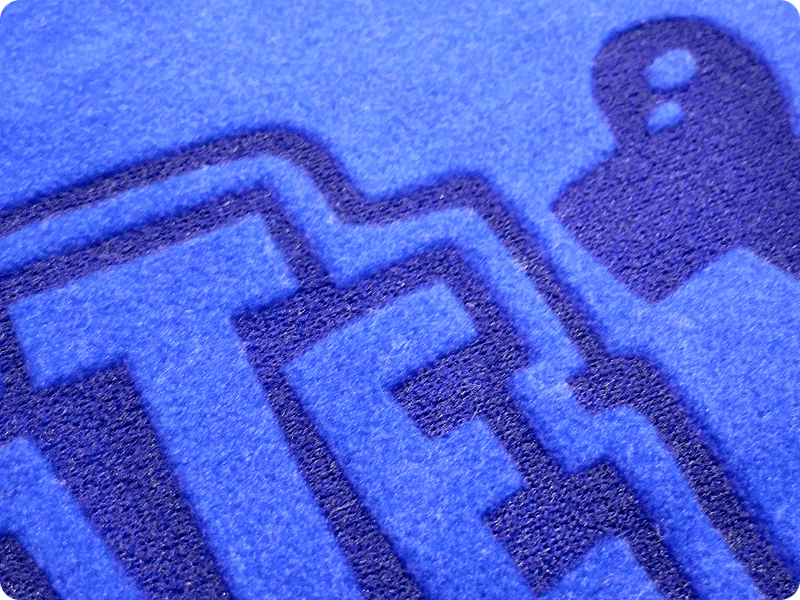

Laser engraved fleecewear

The laser is a very versatile tool and can be used on different materials to achieve original effects.

Among these, the fleece engraving process reproduces the dévoré effect, which is obtained by removing the surface part of the fabric, thus revealing the underlying weave, with a three-dimensional and tone-on-tone rendering.

This personalisation technique goes particularly well with embroidered details.

|

|

Faux leather patches

The use of lasers enables engraving work to be carried out on leather and faux leather.

The effect of a laser engraving is similar to burning or branding and is indelible and permanent. The tool is very precise and can engrave lettering, images and logos.

The finished label is then sewn onto trousers and jeans.

|

|

|

|

Is made in Italy an added value of your company? Communicate it by applying the tricolour flag to your workwear!

The woven labels are of excellent quality, guaranteeing the strength of embroidery and the lightness of a label. They are made of 62x30mm fabric and are hot pressed onto the garment. They are so light and durable that they are suitable for customising all types of workwear.

|

For more informations and find out what is the more suitable personalisation technique for your workwear or ask for a quotation, contact us at: putmylogoonit@castbolzonella.it